Shenzhen Xingtaida Electronics Co., Ltd.

TEL:+86 136 0044 1592 0756-3632169

E-mail:xtd@cable-sz.com

Adress:No.2 Factory Building, Jinding Huaguan Industrial Park, Hi-Tech Zone, Zhuhai, China

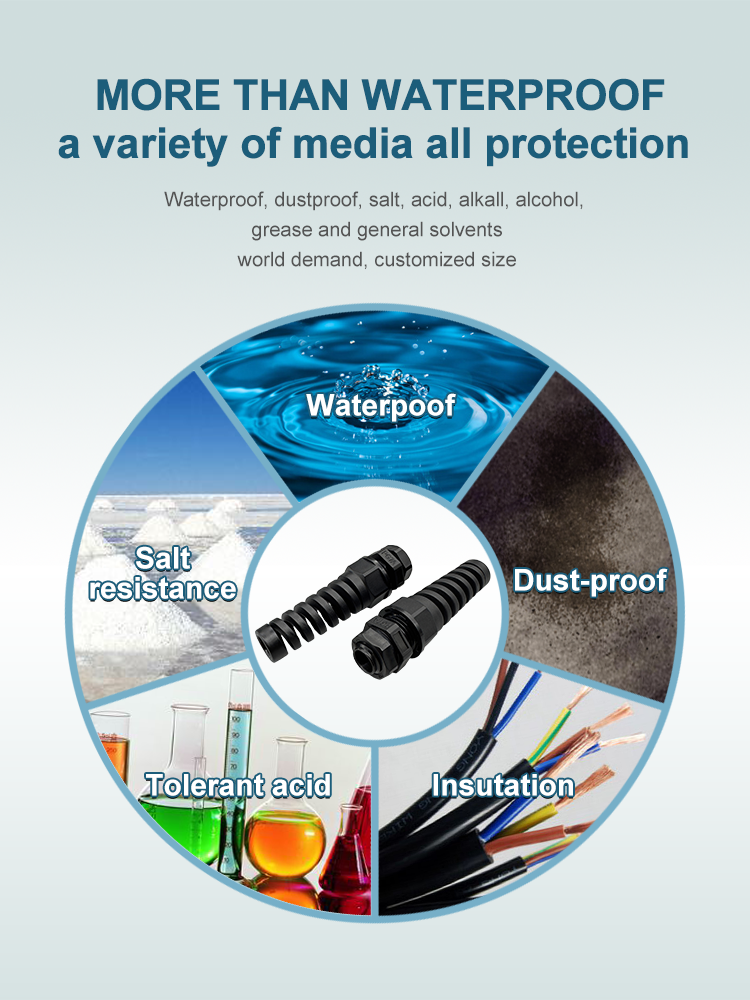

The material characteristics of nylon anti bending joints mainly come from the nylon material used (usually nylon 6 or nylon 66), which endows the joint with good mechanical properties, chemical resistance, and environmental adaptability. The following are several key characteristics of nylon anti bending joint material:

1. High strength and toughness

Impact resistance: Nylon material has good mechanical strength and toughness, can withstand large mechanical stress and impact, and is not easily broken or deformed. This enables the nylon anti bending joint to maintain a stable structure under repeated bending or stress.

Wear resistance: Nylon has good wear resistance, and joints can reduce wear and extend service life in environments where they come into long-term contact and friction with cables and equipment.

2. Temperature resistance

High and low temperature resistance: Nylon materials have a wide temperature range and can usually be used normally at temperatures between -40 ° C and+100 ° C. Some reinforced nylon materials can even withstand higher temperatures. Therefore, nylon anti bending joints are suitable for high or low temperature environments.

3. Excellent anti-aging performance

Anti UV aging: Nylon material has strong resistance to UV rays, and even if used for a long time under direct sunlight, it is not easy to age or experience significant physical performance degradation.

Long term stability: Nylon materials can maintain a long service life in outdoor or industrial environments, and are not easily brittle or degraded.

4. Chemical corrosion resistance

Oil and acid alkali resistance: Nylon has good resistance to chemical substances such as oil, alkali, and acid. Therefore, in environments with oil stains, corrosive liquids, etc., nylon anti bending joints can effectively resist the erosion of these substances on the material.

Solvent resistance: Nylon also has good tolerance to most common solvents and is suitable for use in complex industrial chemical environments.

5. Electrical insulation

Good insulation performance: Nylon material itself is an excellent electrical insulator, which can effectively prevent current leakage and short circuit problems when used in cable connections or electrical equipment, ensuring the safe operation of electrical equipment.

6. Lightweight

Lightweight: Nylon material is relatively lightweight, and compared to metal joints, nylon anti bending joints are lighter in weight, making it easier to assemble and maintain equipment, while also reducing the total weight of the equipment.

7. Easy to process and shape

Good formability: Nylon has good injection molding performance and can be used to manufacture various shapes and specifications of anti bending joints through complex molds, meeting the needs of different equipment and cables.

Smooth surface: Nylon material has a smooth surface, and the smooth inner wall of the joint can reduce cable friction and minimize wear on the cable.

8. Environmental friendliness

Recyclability: Nylon material has a certain degree of environmental friendliness, can be regenerated and recycled, and conforms to the trend of modern industry's environmental protection requirements.

In summary, the wide application of nylon anti bending joints is due to their material characteristics such as high strength, wear resistance, temperature resistance, corrosion resistance, and good electrical insulation. They can provide reliable protection for cables and equipment in various harsh environments.